Installation

When creating fiber cement facade panels, it was taken into account that these products are intended for use in ventilated facade systems.

The design provides reliable wall protection, timely removal of moisture from gaps, and heat retention. A ventilated facade with KMEW fiber cement panels combines innovative solutions, modern technologies, and compliance with environmental standards in construction.

Key steps for installing fiber cement panels

Installation is possible on almost any type of wall (brick, wooden, reinforced concrete), including walls with a metal or wooden frame.

For panels 14 mm thick, a wooden substructure is used as a more economical option. For greater system reliability, panels 16 mm and thicker are installed on a metal substructure using clips.

Before installation, the strength of the exterior walls is checked to determine the feasibility of fixing the substructures.

For panels 16 mm and thicker, metal substructures certified to Russian Federation standards are used.

For wooden substructures, wooden battens at least 50 mm thick from hardwood species are required.

To ensure heat retention in the building, the following insulators are used:

Basalt wool with a density of at least 80 kg/m³.

Fiberglass wool with a density of at least 30 kg/m³.

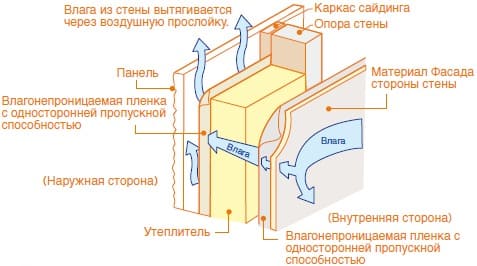

A vapor-permeable membrane certified to Russian Federation standards is installed over the insulation.

Sealing of panel ends and joints is performed.

Possible panel damage is touched up using matching repair paint.

Installation quality is checked.

You can find the Technical Solutions Album in the DOCUMENTS section.

Three Key Features of the KMEW Ventilated Facade

1. Elimination of the dew point within the wall structure.

One of the protective functions of the KMEW ventilated facade is the removal of moisture from the building and the elimination of the “dew point” within the wall mass itself.

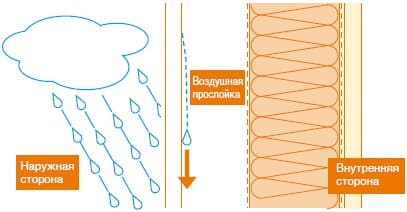

2. Protection against rain penetration.

Raindrops that hit the wall fall down through the air gap and drain away along the starter strip at the bottom.

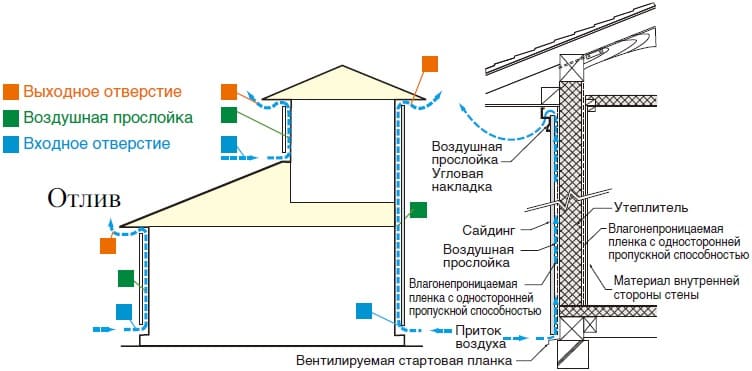

KMEW Ventilated Facade Cross-Section

The KMEW ventilated facade consists of several elements:

Inlet ventilation gap – minimum 10 mm

Main ventilation cavity – approximately 40 mm, filled with airflow

Outlet ventilation gap – minimum 10 mm

We will advise you on which plinth and ceiling materials to use for optimal performance.

Вас может заинтересовать:

- Обслуживание

- Декларация по пожарной безопасности

- Погодоустойчивость фасадных панелей KMEW — сохранение цвета и размеров

- Функция очистки воздух

- Покрытие фасадных панелей KMEW

English

English

Русский

Русский

Eesti

Eesti

/

/

Català

Català

Español

Español